Download PDF FAQ’s

FAQ’s

How does Timestrip Plus work?

A colored liquid dye housed in a blister is held adjacent to a specialized microporous membrane. Upon

squeezing the blister, the dye comes into contact with

the membrane. If the temperature of the product is

below the stated ‘stop’ temperature, the dye changes

state to solid form, and it is unable to move through

the membrane. If it rises above the threshold temperature, it changes to liquid form and moves at a

precise rate through the membrane. A scale printed

on the surface indicates the amount of time above

the threshold temperature.

Why do they have a start/threshold temperature and a ‘stop’ temperature?

The freezing point of a liquid is always lower that

its melting point. For example, water doesn’t freeze

at precisely 0˚C (32˚F), it freezes when the first ice

crystals form, which is typically lower than 0˚C. Its

melting point is precisely at 0˚C however. Timestrip

Plus™ works by diffusion of liquids that form crystals

and therefore the ‘stop’ temperature is lower than

that of the precise starting point. More technically, the

behavior of liquids in a membrane is different again

to normal freezing due to many other factors, all of

which we take into account when defining the products. We offer the best performance in this category

of products

Do I need to condition the products prior to activation?

No. Unlike other threshold temperature products,

Timestrip Plus™ does not require pre-conditioning.

You need to activate above the product’s threshold

temperature, as you cannot squeeze the blister in

solid form. Immediately after activation, stop the

process by placing below the ‘stop’ temperature. The

fastest way to do this is by placing in an environment

much colder than the stop temperature for a short

period of time

Do they have any special storage requirements before activation?

No, unlike other threshold temperature products, they

can be held at ambient temperatures.

Do they have a shelf-life?

Timestrip Plus™ shows no degradation in performance over time. We only provide a general guideline

of 2 years due to the pressure sensitive adhesive on

the bottom, which allows you to use the product as

an adhesive label. All standard adhesives have such

disclaimers regarding their shelf life.

Can Timestrip Plus indicate if a temperature has fallen below a certain point?

Timestrip Plus™ can only show ascending temperature excursions. We have other products that do this

type of descending temperature indication.

How accurate are they?

+/- 1˚Celsius for the temperature component and +/-

15% for the time component

What can they be used on?

Anything where elevated temperatures are an issue.

Common applications are frozen or chilled foods,

medicines, vaccines, blood products and adhesives.

Can you customize for us?

We have a growing range of standard products that

meet most cold chain requirements. As a general

rule, if you require more than 50,000 units, we can

customize the print, and in many cases, even the melt

temperature, although we have an extensive existing

range. There is a premium for this service. We can

also quote on custom carrier cards and backing labels,

if you need to provide instructions, add other languages, or a form to provide a permanent record.

Timestrip Plus™ compare with data loggers?

There are several fundamental differences, and in

some cases data loggers and Timestrip Plus™ can

be used in complementary ways to help monitor cold

chain integrity. Timestrip® also sells an exceptional

range of data loggers if more appropriate to your

requirement. Data loggers are expensive and typically

are designed to go on a large shipments, typically

need to be returned to be read, and to be used again

to justify the expense.

Timestrip Plus™ are inexpensive, single

use products that can be used on a large shipment,

but also on carton or even single dose level. Data

loggers provide a full history of temperature from the

time of activation. Timestrip Plus™ records how long

a product has been above its threshold temperature,

but cannot tell you when the breach or breaches occurred. Timestrip Plus™ is most often used to monitor and validate the “last-mile” of the cold chain where

the product gets closest to its eventual use. Data

loggers and other digital recorders are too expensive, and complicated to read and interpret. Timestrip

Plus™ give end users immediate visual messages

that can then form the basis of a “use/don’t use”

decision for temperature sensitive goods- even by

untrained recipients

What is the accuracy of the hour marks?

Every Timestrip Plus™ product is calibrated to a temperature of 2˚C above its stated threshold temperature. For example, Timestrip Plus™ 12˚C is calibrated

to a temperature of 14˚C. When the product breaches

its threshold temperature and is held at a constant

temperature(i.e. isotherm) of 14˚ C, it will reach the 1

Hour print mark within 1 Hr (+/- 15% in time).

What is the maximum run-time Timestrip Plus™ range can offer?

Timestrip Plus™ products use low viscous liquids and

inherently fast progressing. Typically the progression

rate of these liquids is roughly 15–25mm in 24 Hours

at room temperature. Timestrip Plus™ products feature a blister located on top of the product, reducing

the available window. Usually, the available run-out

window is limited to a maximum of 12mm which is

roughly correlated to a maximum of 24 Hours. This

value is liquid and temperature dependant thus can

change from product to product.

Why is there an activation window and a runout window?

Timestrip Plus™ products are implemented by activating the product at temperatures above the threshold and placing them below the stated ‘stop’ temperature, which stops the dye from moving throughout

the window. In order to provide a breach/no-breach

indicator there are 3 – 3.5 mm of progress from activation to the run out window. This distance correlates

to roughly 30–60 minutes and is strictly liquid and

temperature dependant ( it can change from product to product). Therefore the run-out window starts

showing breaches lasting 30-60 minutes depending

on the product needed.

What happens at elevated temperatures?

Due to the nature of liquids, higher temperatures

reduce Timestrip Plus™ dye viscosity. The correlated

result is faster/shorter run-times ( the progressing

colored dye will reach each printed time-mark sooner

than intended).

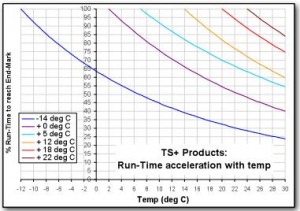

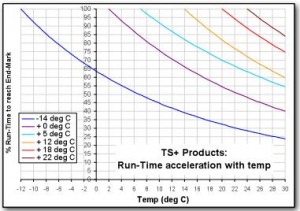

This graph represents the run-time acceleration with

temperature of different Timestrip Plus™ products.

For example, Timestrip Plus™ 0˚C is calibrated to

2˚C (pink line). When the product

is held at an isotherm of +2˚C it will reach each printmark (i.e. 1, 2, 4, 8 Hour, etc.) within the

exact time (i.e. 1, 2, 4, 8 Hour, etc.). However,

if the product is exposed to an isotherm of +10˚C

then it will reach each print-mark with only 75% of the

run-time. In other words, it will reach the 1 Hour timemark within 75% of 1 Hour (45 minutes), the 2 Hour

time-mark within 75% of 2 Hour (90 minutes), the 4

Hour time-mark within 75% of 4 Hour (180 minutes),

etc. At 23˚C the progressing front-line will reach each

print-mark with only 50% of the run-time, etc…

How are Timestrip Plus™ products evaluated for their time accuracy?

Timestrip Plus™ products are polymeric multi-layer

indicators. They are based on spontaneous lateral

wetting by a colored liquid inside a porous substrate

and not a chemical reaction. Each production batch

(7000 – 8000 products) undergo restrictive quality

control tests to validate its time accuracy.

This is conducted via a specially designed

computer vision software (TSCV) which analyzes

scanned photos of seven randomly-selected products from each batch (roughly 0.1% of the population). The photos are taken at different elapsed

times and the tested products are placed at their

designated temperature through the entire test period. The software automatically analyses the lateral

progress and the elapsed time of each product

tested and the data is presented numerically and

graphically in a specific file which is obviously batchrelated. This data is translated into a final release

report which is attached to the outgoing product

batches.

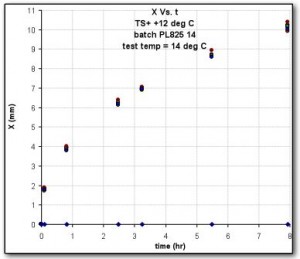

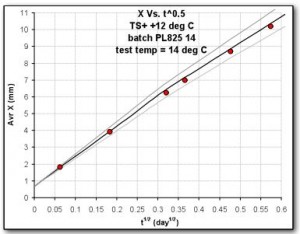

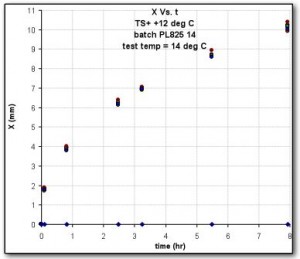

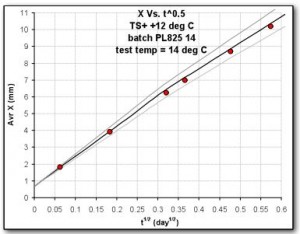

An example for such run-time accuracy analysis of

a specific production batch (Timestrip Plus™ 12 ˚C,

PL825-14) is given below. The first graph represents

the individual progress of the seven representative

products versus time. The second graph represents

the average progress of the seven tested products

versus the square root of time together with the

required progress (continues black line) and borders

of acceptance tolerance (two continues grey lines).

In this case the run-time accepted tolerance of the

averaged group is +/-15%.

What is a Timestrip®?

Timestrip® is a unique, patented timer that monitors

how long a product has been open or how long it has

been in use. Timestrip® is a single-use, disposable

product that can be produced to monitor time periods

ranging from 5 minutes to over a year

How does it work?

Timestrips® should be activated when the product is

first opened or used.

- Activate by squeezing the button flat.

- An activation line appears to show that the Timestrip® is working.

- Stick the Timestrip® on or near to the device it is monitoring.

- The liquid gradually moves across the white viewing window. Read how long the Timestrip® has been active by simply looking at the scale that is printed by the window.

- Dispose of the Timestrip® every time you change the device it is monitoring.

- Activate a new Timestrip® and attach it to the replacement device.

Specifications

- Dimensions:standard size is 19mm x 40mm.

- Approximately (3/4” x 1 1/2”)

- Time period:capability of monitoring time periods of between 5 minutes and 12 months.

- Temperature:Timestrips® are calibrated to monitor time at a specified average temperature selected from a range between -17˚C (1˚F) to +40˚C (104˚F).

- Accuracy: When used within the calibrated temperature range, accuracy is +/-10 to 15% depending on the model.

- Adhesive:can be supplied with a wide range of perm-peel or permanent adhesives on the underside of the Timestrip®, or with no adhesive at all.

- Packaging:can be supplied loose, in boxes, poly bags or custom packs.

How do I know if I activated the Timestrip®?

After squeezing the button flat a line will emerge in the

window to show that the Timestrip® is activated. If the

activation window is already red then do not use

Does it matter how it is oriented?

Orientation has no impact on the way it works.

Is the liquid safe?

Yes. We only use food-grade oils and non-toxic colourants in our formulation.

What happens if the liquid is ingested?

In the unlikely event that the liquid leaks from the

Timestrip®.and comes into contact with skin, simply

wash

with soap and water. If the liquid comes into contact

with eyes, rinse immediately with plenty of water and

seek medical advice

Are they waterproof?

No. Timestrips® should not be submerged in water,

but are splash-proof.

Can you use different colored liquids?

We are limited to using a red colourant in most

cases although certain products use blue.

Will the Timestrip® tell me when the product is no longer fresh?

Timestrip® only records the passage of time after

it is activated and therefore cannot guarantee the

quality or fitness for purpose of the product with

which it is used.

Is accuracy affected by temperature or altitude?

Timestrips® are accurate to within +/-10 to 15%

depending on the model, provided they

are used in line with the stated temperature.

If the product is stored at a higher than

intended temperature the Timestrip® will

advance at a faster rate, and vice versa at

lower temperatures. For detailed technical

information please contact us. Altitude does

not affect accuracy

What is the shelf life of a Timestrip®?

Timestrips® can be stored for a minimum of 3 years

and require no special storage conditions.

Can Timestrips be customized?

It is possible to customise the print, shape, dimensions and type of adhesive, subject to volumes, tooling costs and set-up charges.